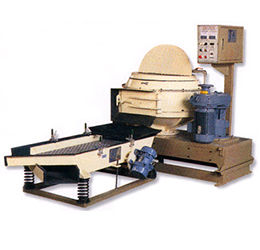

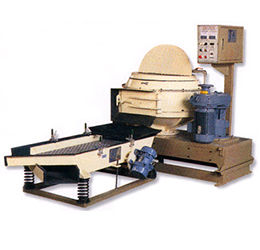

Rollflow Polishing Machine

JR Type

This machine is consisted with fixed polishing drum and rotating polishing disc. The disc rotation motion creates centrifugal force, which makes the polishing stone and the work pieces hit the wall of the fixed drum. This makes vortex and the polishing stone and the work pieces travel to rotating discs back and force. It is also called a vortex type polishing machine because it collides with the polishing stone and work pieces to create vortex resulting in strong cutting force or make the surface more gloss.

Product Characteristics

- 6 times higher efficient than the vibration polishing machine through the strong vortex flow

- possible to control at slow speed, resulting to eliminating cutting or reducing any damage

- uniform quality and the intensity of illumination

- easy to observe the polishing process and it’s efficiency though naked eyes

- easier to insert or discharge the work pieces from chamber comparing with "Centrifugal Polishing Machine"

Product Usage

It is suitable for removing burr and gloss level treatment after fabrication of machining automobile parts, hydraulic parts, casting parts, steel shot, hard metal tools, etc.

Note: suitable for relatively higher level of hardness material.

Specification

| Item \ Model | JR_100 | JR_200 | JR_380 |

|---|---|---|---|

| Polishing Chamber Volume (L) | 100 | 200 | 380 |

| Polishing Capacity (L) | 65 | 130 | 250 |

| Main Motor Power (HP) | 5 | 10 | 15 |

| Polishing Chamber Size (mm) | ø600*400H | ø830*430H | ø1050*470H |

| Equipment Size (L*H) | 1600*1300 | 1850*1400 | 2800*1400 |

| Equipment Weight (kg) | 1050 | 1200 | 1400 |